Recycled plastic products: How are they made?

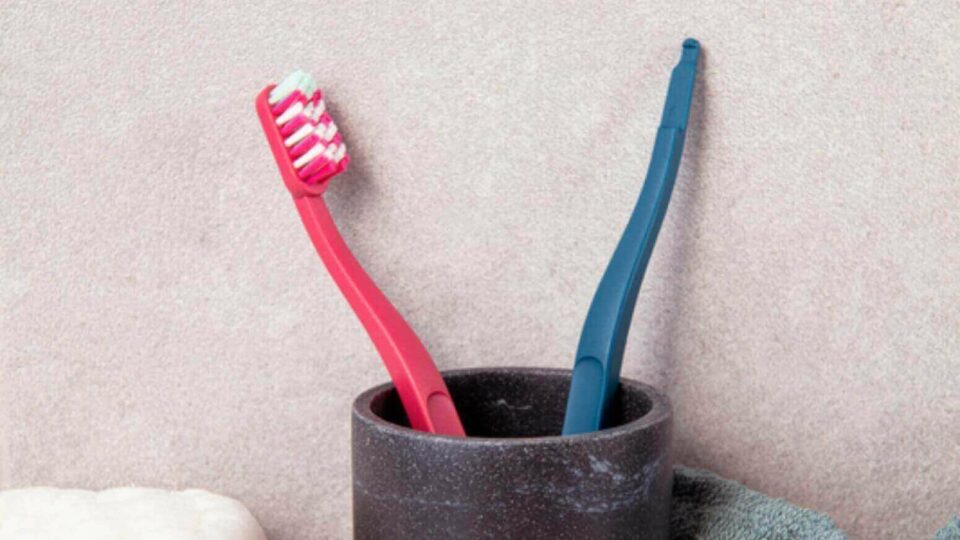

When a product is made as a toy, or to use in our mouths, the rules and regulations for safety are much higher. So how do we make a toothbrush that is safe to use, from recycled plastics?

Making products from recycled plastic can be a challenging ordeal, to ensure both the quality and pureness of the material. Did you know that mono-materials are much easier to recycle than poly-materials? And that good quality recycled plastic can be hard to get by in large enough amounts? Still, using what is already in circulation instead of introducing even more virgin plastic is definitely worth it, from an environmental perspective! Let us guide you through the journey from a yoghurt cup, or the alike, to a toothbrush, and how we ensure safe products that don’t compromise on effectiveness.

1. Gathering

The plastic used in our recycled oral care products is made from used food containers such as yoghurt cups. Buying used plastic for our production contributes to giving it value, and thus contributes to make it too valuable to end up in nature, or simply be incinerated for energy recovery.

2. Sorting

The plastic is meticulously sorted, to ensure only the type, quality and safe plastic that we need for our production.

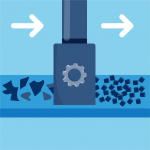

3. Shredding

The recycled, sorted plastic is shredded, for even more sorting and quality testing.

4. Water sorting

The shredded plastic is conveyed into a large water bath, where buoyancy sorts the materials even more, to ensure any unwanted elements or materials are excluded.

5. Drying

The plastic is dried off a first time, after the mentioned sorting in water.

6. Washing

The flakes are then washed with detergents and heated water, before dried again.

7. Making into pellets

The shredded plastic is melted down, extruded and cut to pellets, before testing the specific material quality acquired.

8. Testing

Before approving the batch for shipment to our manufacturer of toothbrushes, the pellets are tested and inspected for a range of things like health safety, odor, color, breakage and other material properties.

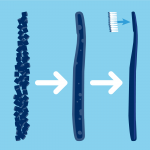

9. Making of toothbrush

After receiving the approved pellets, the toothbrushes are made. The handle is made by injection molding, and then the handle and bristles are assembled.

10. More testing

Previous testing was executed to ensure that the material itself is good enough. After production of the toothbrushes they undergo the same quality tests as all of our toothbrushes, to ensure that the toothbrushes made from recycled plastic are no lesser in quality and effectiveness.

11. Tada!

The product is ready to be distributed to one of our 50 markets worldwide.

You might want to read

Changeable brush heads: Jordan’s newest toothbrush!

Why throw away the whole toothbrush, when it’s only the bristles that wear out? Jordan is introducing Jordan Change – changing habits for you and…

Read more

How to get the most out of your toothpaste tube

Making your toothpaste last longer is a sustainable choice in itself, with reducing how much product goes to waste. On our Green Clean toothpastes, we…

Read more

#EasyGreenChoice

April is our #EasyGreenChoice-month, where we highlight choices for a more sustainable everyday life. Join us in celebrating both small and big ideas by sharing…

Read more